PCBA (Printed Circuit Board Assembly) manufacturing is a crucial process in the electronics industry, where components are mounted on a printed circuit board to create a functional electronic assembly. This article provides an in-depth look into the pcba manufacturing process, its key stages, and the importance of quality control.

Understanding PCBA Manufacturing

PCBA manufacturing involves several complex stages that transform raw materials into a finished, functional electronic product. Here’s a detailed breakdown:

1. Design and Prototyping

The process begins with the design of the PCB. Designers use CAD (Computer-Aided Design) software to create a schematic diagram, which serves as the blueprint for the PCB layout. Once the design is finalized, a prototype PCB is typically produced to ensure that it functions correctly.

2. PCB Fabrication

The PCB fabrication process starts with the production of the bare PCB. This involves:

- Substrate Preparation: A layer of non-conductive substrate material, such as fiberglass, is coated with a thin layer of copper on both sides.

- Etching: Using a chemical process, unwanted copper is removed from the board, leaving behind the desired copper traces that form the circuit.

- Drilling: Holes are drilled into the board to accommodate through-hole components and vias (connections between different layers of the PCB).

3. Component Procurement

Once the bare PCB is ready, the next step is to source electronic components that will be mounted on it. These components can vary widely in size, complexity, and function, from tiny resistors and capacitors to large ICs (Integrated Circuits).

4. PCB Assembly

The PCB assembly process includes:

- Solder Paste Application: A stencil is used to apply solder paste onto the PCB, which adheres to the copper pads where components will be mounted.

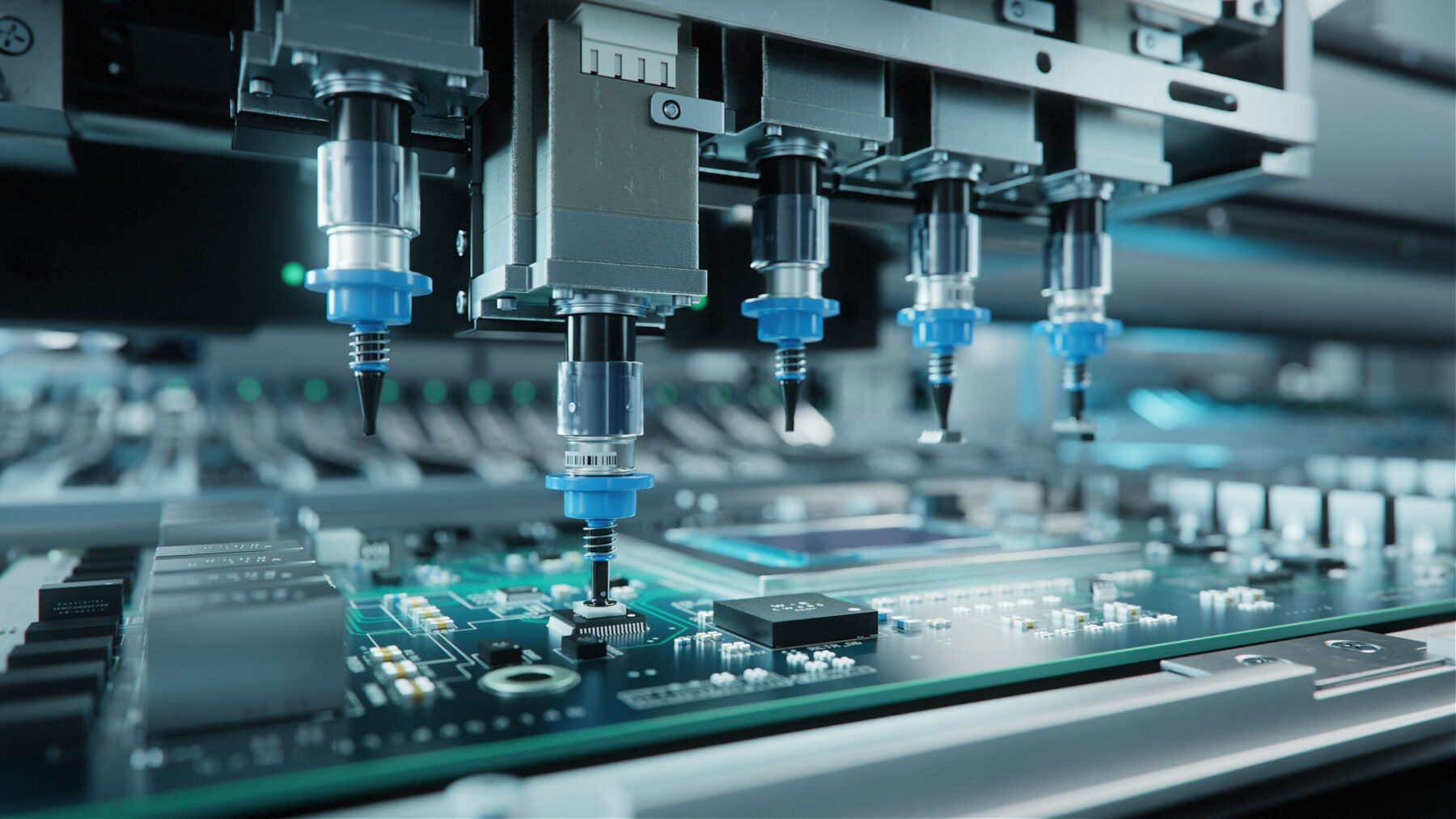

- Pick-and-Place: Automated machines precisely place surface-mount components onto the PCB using the solder paste as adhesive.

- Reflow Soldering: The PCB is passed through a reflow oven where the solder paste is heated, melting the solder and permanently attaching the components to the board.

5. Quality Control

Quality control (QC) is crucial throughout the entire PCBA manufacturing process. QC checks include:

- Automated Optical Inspection (AOI): Machines inspect the PCB for missing components, misalignment, or soldering defects.

- Functional Testing: Testing the finished PCB to ensure it operates as intended.

6. Packaging and Shipping

Once the PCBs pass QC, they are packaged according to customer specifications and shipped to the assembly line or end customer.

Importance of Quality Control

Quality control is paramount in PCBA manufacturing to ensure that the final product meets the required standards of reliability, functionality, and durability. Even minor defects in soldering or component placement can lead to malfunctioning electronics or premature failure.